With targets to deliver 50GW of offshore wind by 2030, and growing momentum in tidal, wave and floating solar, the UK’s sets out a bold vision. But this transition is far from straightforward.

The industry is facing a growing number of bottlenecks across , in project approvals, in grid connectivity and, in cost and delivery risk. These are causing significant delays, driving up costs and, in some cases, . Developers, manufacturers and engineers are all working to address these barriers by pushing the boundaries of what technology can achieve - delivering smarter, more sustainable solutions to support the next generation of offshore energy projects.

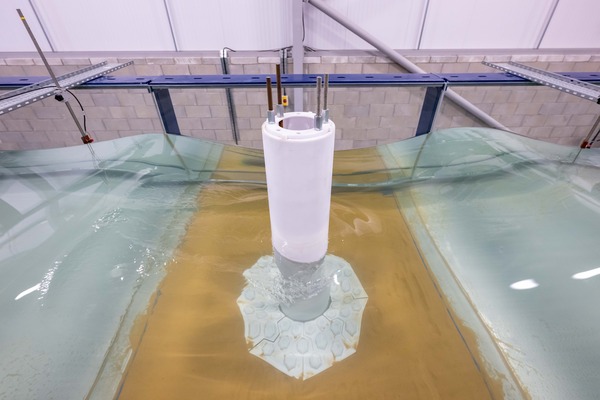

We’ve seen this first-hand with developments like , our scour protection system designed to prevent seabed erosion around offshore wind foundations. This technology offers a more cost-effective, lower-carbon alternative to traditional methods such as rock dumping. However, after investing millions of pounds in its development, when it came time to test and validate it, we faced significant delays when it came to securing access to large-scale testing environments capable of replicating real offshore conditions.

Eventually, after a considerable wait, testing took place, but this is not an isolated challenge. Across the UK and Europe, commercial and academic testing facilities are in short supply and are oversubscribed. For an industry that urgently needs to accelerate deployment, these limitations are more than just a technical hurdle - they are a threat to progress.

Faced with these barriers, and recognising the risk they pose not just to our own innovations but to the wider industry, we made the decision to invest in the infrastructure ourselves - .

What sets this facility apart is its practical, industry-led design. Unlike larger, heavily booked commercial tanks, it offers shorter, more flexible booking windows, allowing developers to run focused test campaigns without long lead times. Its modular layout enables quick setup, reconfiguration and reduces manual handling of equipment - speeding up testing cycles and reducing operational downtime.

A fully removable sand bed and sediment tray allow developers to conduct detailed seabed interaction studies, helping to simulate how offshore technologies perform in dynamic marine environments. The tank can also replicate site-specific wave and current conditions, including the North Sea’s JONSWAP wave spectrum, exposing equipment to realistic scenarios and reducing technical risk.

The tank’s flexibility also makes it suitable for a wide range of marine energy applications, including fixed and floating wind, tidal, wave, and even conventional offshore energy systems. And while niche applications like floating solar are still emerging, in principle, if it goes underwater, it can be tested here.

This investment was never about solving a challenge for us alone. From the outset, we recognised that the barriers we faced were shared by innovators across the offshore energy industry. That’s why we developed the facility to serve a greater purpose - providing the sector with a faster, more accessible route to testing and validation.

Based in Aberdeen, a recognised centre of offshore engineering excellence, this facility strengthens the region’s role as a hub for UK and European offshore innovation. By improving access to practical, real-world testing, it supports developers and innovators who are working to bring the next generation of energy solutions to market.

As we continue to navigate the complexities of the energy transition, investments like this can unlock real value - not just for individual projects, but for the future of the entire offshore energy sector.