Tip #1: Tribology - Assume All Hydraulic Components are Designed Equally

Believe it or not, maintenance begins during the design phase.

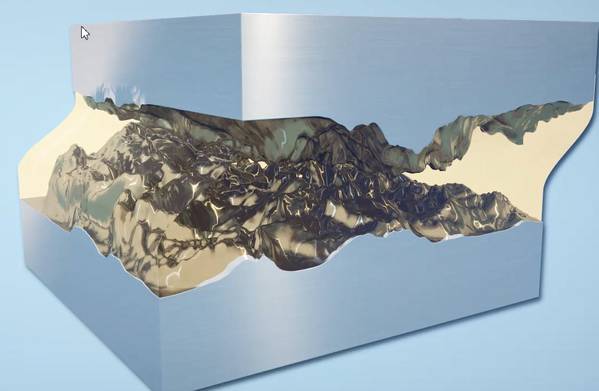

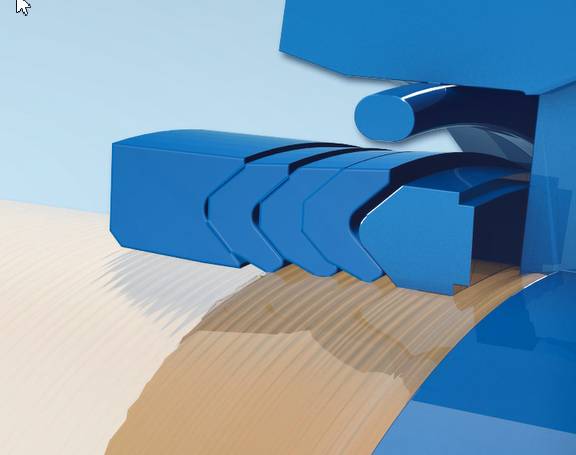

Moving parts create friction, and friction can lead to wear, ending in premature failure, especially when tribology is ignored. In order to have a long-lasting hydraulic system, it is critical to specify operating conditions and environment during the project start. When all conditions are considered, it is possible to select the right component with the ideal tribological configuration for lasting component life.

Learn more about the importance of offshore equipment hydraulic maintenance during a free webinar entitled: “5 Easy Ways to Ruin Your Ōʶ„¶Ä³”ĄĻ»¢»ś Equipment: Lessons Learned in Hydraulic Maintenance,” scheduled to be held October 28, 2020 at 11 a.m. EST.

Sign up .

Image Courtesy Bosch Rexroth.

Image Courtesy Bosch Rexroth.